What is ECA?

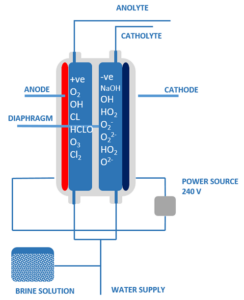

ECA stands for Electro Chemical Activation.

ECA is a patented technology first invented in Russia and has been under development for over 40 years.

The activation process uses water, salt and electricity and produces a potent and natural disinfectant and detergent.

What is ECA? How does ECA work?

Microbes, like other living things need a stable energy supply to survive. ECA destabilizes and elevates the electrical charge of the water and creates an environment in which microbes cannot survive.

The energy difference between ECA (+900) water and tap water (+200mV) will kill 1 million E.coli in 30 seconds.

ECA works the same as the Human Immune System

When the body comes under attack from invading bacteria and viruses, the immune system immediately responds. The body sends increased numbers of a specific white blood cell called a Neutrophil straight to the invasion site.

Once activated, these cells produce large amounts of a mixed oxidant solution which is effective in eliminating invading microbes and pathogens.

The oxidant produced by the white blood cells Hypochlorous acid or (HOCl) is amongst the most potent natural disinfectants. It is non-toxic to humans, and is highly effective as an antimicrobial agent with rapid action.

HOCl is generated under specific electro-chemical conditions using a combination of water, salt (NaCl) and electricity. By using our specialized hygiene generators, NIXOL d.o.o. is able to produce HOCl of the highest quality and efficacy, liter after liter.

HOCI is extremely effective at eliminating all pathogens and food spoilage microbes including spores.

Benefits of ECA

ECA solutions comprise of salt, water and electricity and are safe for contact with humans.

ECA solutions comprise of salt, water and electricity and are safe for contact with humans.

ECA solutions are highly effective in destroying bacteria, spores, fungi, viruses and yeasts and molds.

With conventional chemical sanitation, many micro-organisms develop a tolerance or resistance to conventional chemicals as a result of continuous exposure.

Electro-chemically Activated Water (ECA), has a unique mechanism of biocidal action which is distinct from that of chemicals. It has been repeatedly shown that micro-organisms cannot build up a tolerance to ECA technology.

| Average CIP (Cleaning in Place) times may reduce by up to 70% due to the shorter contact time required for effective cleaning and disinfecting. |

| ECA solutions are applied at ambient temperatures with substantial energy savings over conventional chemicals. |

| Up to 60% reduction in water costs due to shorter cleaning and disinfection cycles required. As well as the ability to reclaim CIP solutions for reuse. The two ECA solutions are compatible so rinsing between and after applications is no longer needed. |

| Up to 90% chemical cost reduction by substituting conventional chemicals with the natural ECA solutions. |

| The ECA solutions are reclaimable and can be re-used several times before discarding into the drainage system with no effect on the downstream effluent environment. |

| The ECA products extend the shelf life of fresh produce (including meat, fish and value-added products) and can integrate as an ingredient in sauces/ condiments. |

| There are no significant transport or storage costs. |

| ECA Hygiene Management Devices are installed on-site and solutions are stored in buffer tanks which are available on demand. |

| Anolyte and Catholyte, used on their own or combined are effective in removing and controlling biofilm on all liquid contact surfaces. |

| ECA does not affect taste, color and appearance of the food products. |

| ECA assists in compliance of critical micro standards of products with no preservatives or pasteurization. |

| Broad adoption results in the substantial reduction of toxic effluent. |

| The ECA solutions are safe for unrestricted use by plant personnel, as well as in food and beverage products within all manufacturing and packaging plants. |

ECA IS ecological

Man has become accustomed to resolving many problems with the use of chemicals. The extensive and indiscriminate use of these chemicals has resulted in enormous environmental issues.

The use of these chemical compounds is directly responsible for the pollution of our environment, and causes biocidal and antimicrobial tolerance and resistance within bacteria, viruses and fungi.

We are aware of the importance of reducing our “human footprint” especially in reducing water consumption.

ECA is a 100% natural and efficient cleaning agent. ECA is a viable alternative to chemical cleaning and disinfection in the food and beverage industries.

Who uses ECA?

BEVERAGE PRODUCTION

In the multi-billion dollar beverage industry, it is crucial that manufacturers produce consistent quality. Limited returns allow for sustained enhancement of brand image and equity. Food and beverage processing relies on water as its main ingredient and water quality needs to be of the highest possible standard. Under typical conditions, process or ingredient water is filtered repeatedly before use. While this procedure is effective, other sources of microbial contamination do exist. If left unchecked, these will likely result in product contamination and spoilage.

Through the use of Radical Waters ECA solutions in CIP applications in beverage plants, the results have shown:

- An increase in production time and overall operating efficiency due to shorter CIP’s and down-time and with a potential time saving of up to 70%.

- A substitution of conventional chemicals with the natural ECA solutions may result in savings in chemical costs of up to 90%.

- Water usage may be reduced by up to 60% Radical Waters – Quote Substantial energy savings “All ECA CIP’s” are performed at ambient temperature.

- Improved safety in the hands of workers, as well as being safe to the environment Reduced CIP volumes result in a substantial reduction in the production of toxic effluent.

- ECA will not affect the taste, color and appearance of the treated products Offers a proven solution engineered for an existing or new cleaning in place (CIP) system.

GRAIN AND MILLING

Maximal production output of the highest quality product is paramount to a mill. The busy milling environment requires effective microbial control which is essential to the quality of the milled product. Without an effective decontamination process in place, grain mills risk producing a lower grade product sold at a lower price.

ECA Features for the Miller

- Effective decontamination of raw grain at the conditioning stage

- No product taint or residue carry-over.

- Substantial shelf-life extension of final milled products

- Effective control of fungal spores and other spoilage microbes

- In process bio film removal and control

MEAT PROCESSING

Quality consciousness and compliance with good manufacturing practice is a necessity. This assures optimal quality and extended shelf life of perishable products.

Food-borne outbreaks of Listeria come from re-contamination of meat products during processing. ECA solutions have shown to be 99% effective in the reduction of microbial count.

The remaining microbiocidal activity of ECA after application will also control general microbial build-up and limit further cross contamination.

ECA treated meat products stay fresher for longer and reduce the incidence of food-borne diseases which remain a substantial concern for the health conscious consumer.

In addition, the application of the ECA products in the meat processing environment will result in:

- Eradication of spoilage micro-organisms

- Shelf-life extension

- Decontaminated Offal & sausage casings which result in extended shelf-life of value-add products

- General carcass decontamination

- Working surface disinfection

- General Food-Safety compliance

STARCH PROCESSING

Starch manufacturing is a complicated and chemical intensive process.

Quality production requires low levels of microbial contamination and minimal chemical residue in the manipulation of starch compounds. To produce starch of the highest pharmaceutical-grade, manufacturers must ensure a flawless manufacturing process avoiding exposure to contamination. Without which, starch manufacturers risk producing low grade product at a restricted trade price.

ECA benefits to the Starch Processor

- Integration for Real time Sanitation in Place (SIP)

- Improved assurance of pharmaceutical grade starch production

- Reduction of noxious chemicals such as Sulphur dioxide

- Reduced plant down-time with extended production run time

GRAIN AND MILLING

Maximal production output of the highest quality product is paramount to a mill. The busy milling environment requires effective microbial control which is essential to the quality of the milled product. Without an effective decontamination process in place, grain mills risk producing a lower grade product sold at a lower price.

ECA Features for the Miller

- Effective decontamination of raw grain at the conditioning stage

- No product taint or residue carry-over.

- Substantial shelf-life extension of final milled products

- Effective control of fungal spores and other spoilage microbes

- In process bio film removal and control

SEAFOOD PROCESSING

Shelf-life limits and spoilage of seafood is an ongoing dilemma for processors. In the factory environment, sea water is often used as a medium for transporting fresh fish from one processing point to the next. Throughout processing, sea water becomes progressively soiled allowing micro-organisms to flourish thus pre-empting spoilage. ECA solutions eliminate and control all pathogenic organisms, including Staphylococcus Aureus and E.coli (0157). ECA reduces the overall microbial bio-load of spoilage organisms, thereby substantially reducing the risk of cross contamination.

ECA solutions effectively decontaminate the process sea water which results in a longer shelf life of the processed fish products. ECA can additionally be added into flaking and packing ice to improve the shelf life of fresh seafood for export

ECA benefits in Seafood

- Increased shelf-life

- Addition to packing ice for extended shelf life of fresh products

- Environmental odor control

- Reduction of Total Volatile Nitrogen (TVN) on aged fish

WATER WELLS (Boreholes)

Amongst the measures taken to ensure a constant supply of potable water, has been the development of rehabilitation techniques of boreholes or water wells. This is a practical method of restoring the original capacity (yield) without having to drill additional wells at high cost.

ECA for the treatment of Water Wells is extremely effective in improving well performance by removing biofilm and softening hardened plugging layers within the screen and gravel pack due to a kill efficiency superior to that of most chemicals traditionally used.

- Yields of wells tested increased between 30 and 300%.

- No iron or sulphate reducing bacteria detected after treatment

- Inspection with a borehole camera indicated removal of biofilm and plugging material from well walls and screen sections

- Yield improvement

- Specific capacity improvement between 40 and 400%

- Safe for staff to handle and environmentally friendly

- No special training required to operate

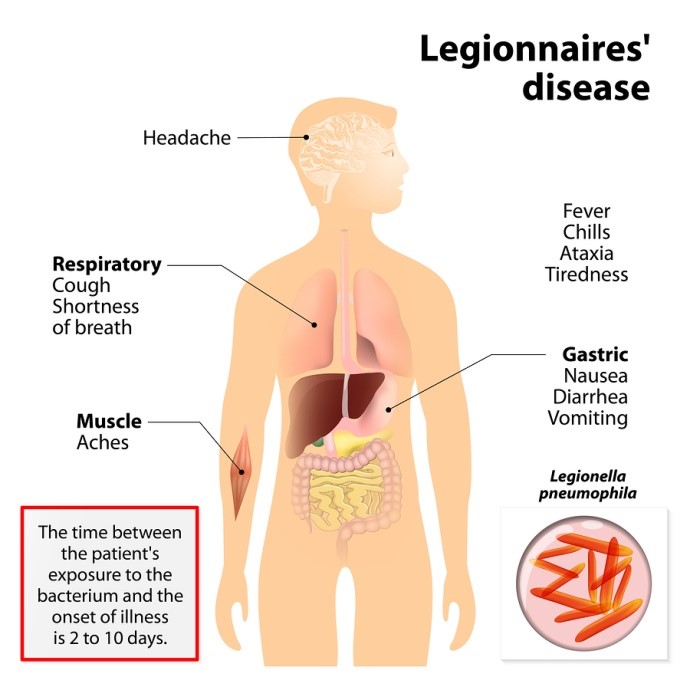

LEGIONELLA

Prevention for hot and cold water systems

Legionella has been identified as a major problem in multi-occupancy buildings such as hotels, hospitals, hostels, schools, military establishments, nursing homes and office blocks.

Worldwide thousands of people become seriously ill or die through infection by this potentially deadly disease. The costs if a buildings water system becomes infected can be substantial not only in terms of human suffering but also financially. If a hotel is identified as a source of infection it can result in forced closure whilst the problem is treated plus possible lawsuits if people are infected. This means substantial loss of revenues and reputation. In addition in many countries if it is shown that the problem occurred due to the negligence of the hotel or ship operators and staff it can result in large financial penalties or even prison sentences for the individuals concerned. Every year hotels throughout the world are forced to close due to this problem often in the height of the tourist season.

Every year people die in hospitals not from the disease that they were being treated for but from infection by this deadly bacteria that they contracted from the hospitals water system. Due to the soaring price of energy many operators of these buildings reduce the overall temperature of the hot water system which can increase the risk of infection by the Legionella bacterium.

Causes and Common Sources of Infection:

Legionella is a type of bacterium found naturally in fresh water. When people are exposed to the bacterium, it can cause illness (Legionnaires’ disease and Pontiac fever). This bacterium grows best in warm water, like the kind found in

· Hot tubs

· Cooling towers (air-conditioning units for large buildings)

· Hot water tanks

· Large plumbing systems

· Decorative fountains

Cooling towers use water to remove heat from a process or building. They are often part of the air conditioning systems of large buildings. In contrast, home and car air conditioning units do not use water to cool, so they do not aerosolize water (spread small droplets of water in the air) and are not a risk for Legionella growth.

The Solution

Our ECA Anolyte generators give the building and ship operators peace of mind that he is doing everything possible to protect the users of the building or ship passengers from infection and consequently minimizes financial and legal risks to themselves.Radical Waters ECA Anolyte generators can be installed in all these buildings or on board the ships to treat the water system on a continual basis not only to remove the infection but to eliminate the risk of reinfection.

It is envisaged that the following methods of Anolyte treatment could be used:

- By dosing Anolyte directly into the water supply and into elements such as a condenser used in air-conditioning systems;

- By fogging Anolyte into air-conditioning ducts or into the atmosphere e.g. in an operation theatre, etc.; and

- By patients affected with legionnaires disease inhaling fogged Anolyte, thereby exposing the Legionella organism to the Anolyte in the alveoli of the lungs.

SWIMMING POOLS AND RESORTS

Wave Parks, Resorts & Large Commercial Pools

Radical Waters, NEX-GEN chlorine generator systems are designed specifically for commercial swimming pool applications. Ranging in sizes from 5 – 80lb’s per day, these chlorine generators are ideally suited for all commercial swimming pools and water parks. The unique design, simplicity and ease of use make this line of generators the most viable alternative to traditional chlorine available on the market today.

With fuel costs that continue to rise and bulk storage of chlorine becoming an ever increasing problem, many pool operators are seeking safer, more cost effective solutions for the sanitization of commercial swimming pools. On-site production of chlorine as a solution of sodium hypochlorite alleviates those unnecessary risks and puts an end to ever increasing chlorine prices and storage issues. The only raw material, salt, is an inert, safe compound that is stored in a feeder on-site and used as required by the chlorine generator.

NEX-GEN technology is the only viable solution to produce sodium hypochlorite on-site as the pool water becomes the raw material for production, instead of fresh water and water softeners. Imagine all the chlorine your facility requires, being made on-site and having the ability to feed multiple pools from a single chlorine generation system.

Radical Waters NEX-GEN chlorine generator systems feature one additional advantage over traditional chlorine and all other chlorine generators: pH neutral chlorine is produced allowing for more stable, effective chlorine to treat your swimming pool or spa.

Benefits:

- Advanced water –cooled power supply for 24/7 operation

- “Plug ‘n play” connections for easy installation & service

- Up to 80lb’s / day on-site chlorine production

- Re-uses swimming pool water for production

- Patented single cell technology

- Advanced power supply and cell stack protection

- Toroidal salt and level control for optimal performance

- 2,500 ppm chlorine produced

- No water softeners or special salt required

FAQs & Glossary

What is ECA?

ECA stands for Electro-Chemical Activation.

ECA is a patented technology first invented in Russia and has been under development for over 40 years. The Activation process uses water, salt and electricity. The activation process produces a potent and natural disinfectant and detergent.

How does ECA work?

Microbes, like other living things need a stable energy supply to survive. ECA destabilises and elevates the electrical charge (Oxidation Reduction Potential or ORP) of the water and creates an environment in which microbes cannot survive.

The energy difference between ECA (+900) water and tap water (+200mV) will kill 1 million E.coli in 30 seconds.

How effective is ECA on microbes?

Aside from effective control of common food spoilage organisms ECA is equally effective against 99,99999999% of dangerous human pathogens which include but are not limited to: Listeria monocytogenes, Salmonella spp and E. coli 0157. Further studies on Bacillus spores, Clostridia, Vibrio cholera and Hepatitis viruses etc. have achieved equivalent results.

Where and how is ECA used?

ECA is universally effective and presents an unchallenged safety profile, it can be applied in all food and beverage environments as well as a water treatment remedy.

Ongoing research, started in the 1970’s has refined a variety of critical application methods in support of good manufacturing practice.

Will ECA control biofilm?

Yes. Biofilm is universally recognized as the primary source of process recontamination. By using continuous dosing, ECA’s unstable micro-electrical charge removes established biofilm and prevents regrowth.

ECA can be applied during food production and as such guarantees safe, continuous disinfection of the process and product.

Glossary

ECA – Electro-Chemical ActivationECAW – Electro-Chemically Activated Water

CIP – Cleaning in Place

ORP – Oxidation Reduction Potential

Anolyte – A strong oxidizing solution with a pH range of 2.5-8.5 and an Oxidation-Reduction Potential (ORP) of +600 to +1000mV

Catholyte – An anti-oxidizing, mild alkaline solution with a pH range of 10.5 to 12.0 and ORP of -600 to -900 mV

Brine – Salt and Water mix in solution

Biofilms – These are a collection of microorganisms surrounded by the slime they secrete, attached to either an inert or living surface

Organoleptic – Sensory properties of a food product, involving taste, colour, odour and feel

CFU’s – Colony Forming Units – is a measure of viable bacterial or fungal numbers/counts

FDA – Federal Drug Administration

SABS – South African Bureau of Standards

EU – European Union

CE Certification – European marking for product groups to indicate conformity with the essential requirements set out in European Directives.